Ngexesha lokusetyenziswa kwexesha elide lomatshini we-biomass pellet, imveliso iya kuncipha ngokuthe ngcembe, kwaye iimfuno zokuvelisa aziyi kufezekiswa.

Kukho izizathu ezininzi zokuhla kwemveliso yomatshini wepellet. Kungenzeka ukuba ukusetyenziswa kakubi komsebenzisi kumatshini we-pellet kubangele umonakalo kwinxalenye yomshini we-pellet, okanye ayizange ifakwe ngokuchanekileyo ngexesha lofakelo, kwaye ayizange ihlangabezane neemfuno eziqhelekileyo. , Ngamafutshane, ukuhla kwemveliso yintloko echaphazela uphuhliso lwamashishini.

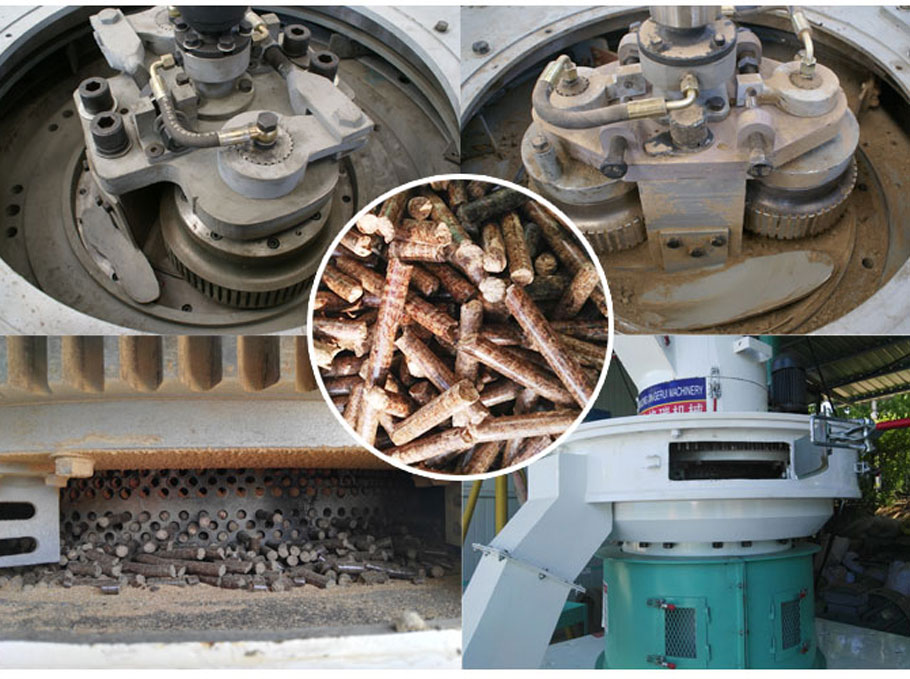

Namhlanje, umhleli we-Kingoro uya kugxininisa ekuchazeni ukuba kubaluleke kangakanani impembelelo yesikrini kwimveliso yomshini we-pellet ye-biomass.

1. Ubude beskrini bumisela ukusebenza kakuhle kwesikrini, kwaye ububanzi beskrini bumisela imveliso yomshini we-pellet ye-biomass. Ukuze kwandiswe imveliso, sinokuhlengahlengisa indlela yokutya, ukwenzela ukuba izinto eziphathekayo kufuneka zondliwe kunye nobubanzi besikrini esigcweleyo, ukwenzela ukuba kungekhona nje Ukukhutshwa kwandiswa, kwaye isikrini sisetyenziswe ngokupheleleyo, sigweme into eyenziwa yimithombo yokungasebenzi;

2. Ukuphucula izinga lokuvula isikrini somatshini we-pellet: isantya esikhulu sokuvula, izinto ezininzi ziya kudlula isikrini ngeyure, nto leyo eluncedo kakhulu ekuphuculeni umphumo wokuhlola kunye nokwandisa imveliso yezixhobo zomshini we-biomass. indlela;

3. Ukusetyenziswa kokuhlolwa okumanzi akukwazi ukwandisa imveliso kuphela, kodwa nokunciphisa ukukhutshwa kothuli okwenziwa ngexesha lokuhlola kunye nokungcolisa umoya, oluncedo kakhulu ekukhuselweni kwendalo. Ukunciphisa i-porosity ye-batter yesikrini, cinga ukongeza iibhola ezibetha ngakumbi ukucoca isikrini kunye nokusebenzisa isixhobo se-ultrasonic. Ukuba i-mesh yesikrini ivaliwe, isixa sezinto ezidlulayo kwisikrini siya kuncitshiswa, nto leyo eya kunciphisa imveliso kwaye igcine isikrini. Imingxuma engathintelwanga ikwayenye yeendlela ezinkulu zokwandisa isivuno.

4. Ukwandisa amandla ombane: amandla ombane ngowona mthombo wamandla oyintloko womsebenzi wokuhlola kunye nowona mandla aphambili okugqiba umsebenzi wokuhlola. Ukunyusa ngokufanelekileyo amandla emoto kunokunyusa imveliso yesixhobo somatshini wepellet;

5. I-angle inclination ye-pellet mill ingalungiswa. I-angle yokuthambekela efanelekileyo iluncedo ekunciphiseni ubukhulu bezinto kunye nokuqaphela ukukhunjuzwa kweeleya ezinqabileyo zezinto. Sonke siyazi ukuba ukuba isixa sokutya sikhulu kakhulu, izinto eziphathekayo ziya kuqokelela ngokungathí sina, ezingayi kukhokelela kuphela ekusebenzeni kakuhle kokuhlolwa Kungathandeki kakhulu ukuba kuthotywe, kwaye kungonakalisa isikrini;

6. Ukunciphisa i-porosity ye-batter yesikrini, cinga ukongeza iibhola ezibethayo ukucoca isikrini kunye nokusebenzisa isixhobo se-ultrasonic. Ukuba i-mesh yesikrini ivaliwe, inani lezinto ezidlulayo kwisikrini liya kuncitshiswa, eliya kunciphisa imveliso. Ukugcina ukuvuleka kwesikrini kungaphazamiseki kwakhona yenye yeendlela ezilungileyo zokunyusa imveliso.

Ixesha lokuposa: May-19-2022